Industrial Epoxy Paint for Concrete Floors: Benefits, Application, and Maintenance

Concrete floors are commonly chosen in commercial and industrial spaces due to their strength and durability. However, over time, these floors can suffer from wear, staining, and other damage, which can affect both their appearance and performance, especially in high-traffic areas. To address these issues, industrial epoxy paint for concrete floors has become a popular solution, offering not only increased durability but also a sleek, professional appearance.

What is Industrial Epoxy Paint?

Is it frustrating to endure stained, damaged, or dull concrete floors in your business or manufacturing plant? Are you looking for an industrial epoxy paint for concrete floors that delivers maximum durability, plus an easy-to-maintain and satisfying graphical look? Industrial epoxy paint is one of the perfect examples of how you can create a hard-wearing, long-lasting, and aesthetically significant flooring solution for your concrete surfaces.

In this article, you will find a brief but detailed overview of industrial epoxy paint, discover what makes it different from other paint types, and learn about all the advantages of its use. Also, we look at some useful equipment that will be needed in the process. This article is aimed at helping facility management, business persons, and contractors by offering them the necessary knowledge and motivation to choose the right flooring options.

Benefits of Industrial Epoxy Paint

There are several advantages of industrial epoxy paint for concrete floors; however, the outstanding durability of the paint is one primary advantage of the product. When properly applied, it can last for many years as well as withstand traffic from humans and vehicles, equipment from industries, chemicals, and frequent washing.

Epoxy also provides a solution for good adhesion since it sticks well to concrete, and the next layer also gives protection in case there is any rough handling. The hard surface is shiny, convenient to clean, and does not support the formation of bacteria or mold.

Epoxy flooring also possesses versatility that comes in different colors and designs, such as metallic epoxy, glitter, and decorative flakes, among others. This means that the facilities can design their distinct floor that may look like a professional one that aligns with the brand of the facility or its interiors.

Common Applications

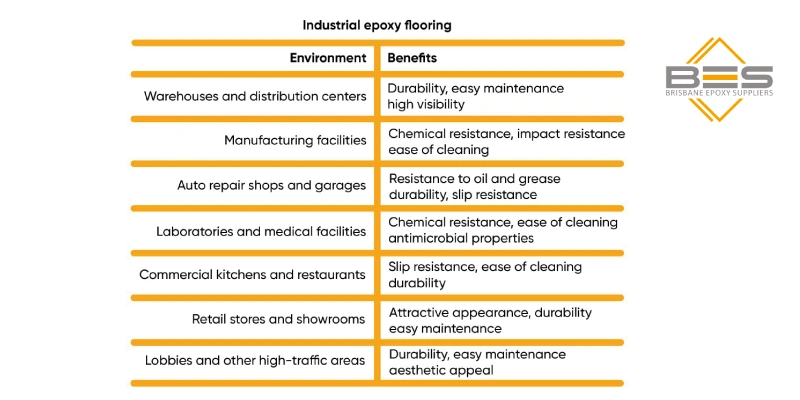

Industrial epoxy paint for concrete floors is widely applied in various commercial and industrial structures and infrastructure. Epoxy used in warehouses and distribution centers proves best for flooring solutions by giving its durability, and maximum traction makes it easy to maintain due to high traffic by humans and forklift operations.

Such places as auto repair shops, garages, and service centers use epoxy because of its ability to resist oil stains and chemicals, as well as hot tire pick-up. Food and beverage facilities like commercial kitchens benefit from the easy-to-clean surface that provides an effective way of meeting high standards of hygiene. You can also use epoxy flooring in hospitals and clinics, shops and schools, gyms, kennels, and so on because of the properties of epoxy coating, which are durability, safety, chemical resistance, and aesthetic appearance.

How to Apply Industrial Epoxy Paint

There are various key factors that you should follow when installing industrial epoxy paint for concrete floors. First of all, adequate preparation of the floor surface. The surface has to be neat, free of dust, and devoid of any oils, greases, or curing agents, among other substances. These are common methods for surface preparation: degreasing, shot blasting, diamond grinding, and acid etching.

Following that, the mixture is applied to the concrete with a roller or squeezer. To burst the air bubbles, use a spiky roller. Add a second layer to increase its thickness and durability. To heighten the color, apply decorative chips or pigments to the second coat. Then allow the floor to cure for another 12-24 hours before it can withstand light foot traffic and 72 hours before it can withstand severe loads.

Maintaining Industrial Epoxy Floors

When installed in industrial settings, epoxy floors are incredibly hard-wearing and can be low-maintenance, but they still need some care to remain in good condition. You should do cleaning of sheds or debris at least daily, and preferably with a sweeper or vacuum, so as not to cause abrasion. In cases of spills, it is advisable to clean the areas quickly before stains accumulate.

Daily cleaning, in most cases, involves damp mopping using a mild cleaner and water. Do not scrub with hard materials or even use strong acids such as bleach, washing with citrus-based solutions, or anything with a cleaner that might bring about fading of the coating. Fix walk-off mats at the door or the entrance to help capture the dirt and moisture that enters the building.

You should protect the components, legs, and other bases of the equipment with pads to avoid damaging the surfaces. When well-coated, an industrial epoxy floor is capable of lasting for many years without requiring a refill.

Industrial Epoxy Materials

While conducting an industrial epoxy flooring project, it’s crucial to use the best kind of products that give the best results and have longevity. You need to supply epoxy kits, pigments, installation tools, and everything to achieve a professional floor coating. Some popular products include:

- Alka 100 Kit: A high-film solids, non-offensive odor epoxy coating with optimum durability and chemical paint resistance by Alka 100 Kit.

- Metallic Epoxy Pigments: Create exceptional finishes and parts that you will never find elsewhere by using metallic pigment powders.

- Epoxy Application Twin Roller Kit: Easily and effectively coat the surface with epoxy using roller and brush sets for professionals.

Nitrile Gloves: Stay safe from epoxy or any solvent with our tough, extra-durable industrial gloves.

Final thought

Industrial epoxy paint for concrete floors is among the most durable and versatile paints to use on commercial and industrial flooring applications. With this innovative coating system, it is possible to upgrade your facility’s concrete floors into a superior performance floor that addresses demands from your operation while at the same time producing an aesthetically attractive space. If durability is what you want from epoxy flooring, high-quality epoxy paints and installation specialists are 2 important factors, especially for such large places.