Epoxy Flakes: Transform Your Floors with Colour, Texture & Durability

Epoxy flakes, also known as decorative flakes, are small, colorful, and randomly shaped particles that are scattered onto the middle or top layer of wet epoxy flooring.

These flakes are typically made from materials like vinyl, acrylic, or polyester, and come in a wide range of colors, shapes, and sizes.

Without these flakes, epoxy flooring has a smooth, solid-colored surface. But when you broadcast the flakes over a freshly applied (still wet) layer of epoxy, they sink slightly into the resin and get locked in place as the floor cures. The result is a beautiful, textured, and decorative finish that adds both visual appeal and practical benefits.

In this article, we’ll explore what epoxy flakes are, take a look at their key benefits and common applications. If you are interested in having epoxy flooring with epoxy flakes, reading this text will be suitable and informative for you.

What Are Epoxy Flakes?

Epoxy flakes—also known by names like Vinyl Color Flakes, Decorative Color Flakes, or Polymeric Flakes—are solid, multi-faceted particles used as a decorative and functional additive in resin-based flooring systems, especially in epoxy resin floor and polyurethane coating.

These flakes are typically made from thermoplastic copolymers, most commonly based on vinyl, acrylic, or polyester materials. Among these, vinyl is the most widely used due to its flexibility and compatibility with epoxy floor. Acrylic is another popular option that offers different properties and aesthetics, depending on the application.

The flakes are usually produced in thin layers, then cut into small pieces with irregular or sometimes uniform shapes. During production, they’re infused with vibrant colors and finishes to create a decorative, textured effect once applied.

When broadcast onto a wet epoxy surface, these colorful flakes become embedded into the coating. After curing, they not only add visual depth and uniqueness but also help reduce surface imperfections and improve slip resistance.

Main Types of Epoxy Flakes

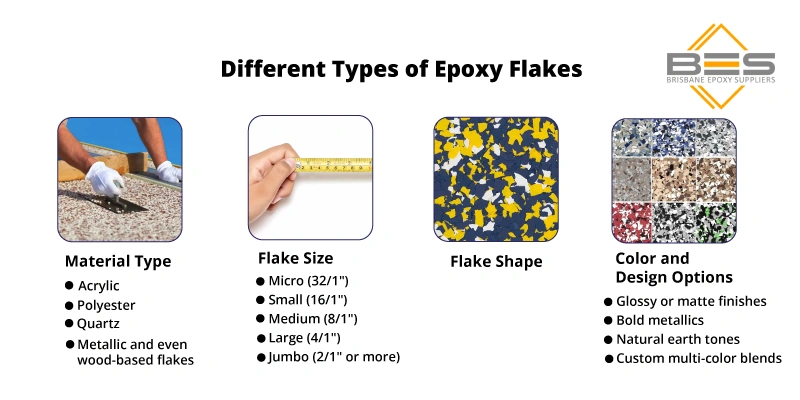

When it comes to creating a stylish and durable epoxy floor, epoxy flakes play a key role in both design and performance. These decorative additives come in a wide variety of materials, sizes, shapes, and finishes, each with its unique effect. Let’s break down the main ways epoxy flakes are categorized:

1. Material Type: What Are Epoxy Flakes Made Of?

The most common type of flakes used in epoxy resin floor systems is made from vinyl, known for its flexibility, durability, and wide range of colors. However, other materials are also used, including:

- Acrylic: Offers a slightly different texture and appearance.

- Polyester: Known for its strength and color retention.

- Quartz: Often used when extra grit or a stone-like appearance is desired.

- Metallic and even wood-based flakes: Great for custom or natural-looking finishes.

If you’re going for a more eye-catching look, metallic flakes for epoxy are an excellent option—they add shimmer and depth that stands out, especially in custom garage or showroom floors.

2. Flake Size: Small Details, Big Impact

Epoxy flakes come in a variety of sizes, which can dramatically affect the epoxy floor texture. Common sizes include:

- Micro (1/32″) – Under 1 mm, for a fine, almost sand-like look

- Small (1/16″) – Around 1.5 mm

- Medium (1/8″) – Roughly 3 mm, a balanced and versatile size

- Large (1/4″) – About 6 mm, more pronounced and textured

- Jumbo (1/2″ or more) – Great for bold designs

Smaller flakes give a smoother, more uniform finish, while larger ones provide a more dramatic, speckled effect. This is something to consider if you’re aiming for a sleek matte finish epoxy floor or something with more visual contrast.

3. Flake Shape: Random vs. Geometric

Most flakes are irregular in shape, which creates a natural, random pattern across the surface. But geometric shapes—like tiny squares or rectangles—are also available. These can be useful when you’re after a more structured or artistic layout, especially in commercial or showroom applications.

4. Color and Design Options

One of the most exciting aspects of epoxy flakes is the endless variety of colors and effects available. From solid colors to mixed color blends, you can tailor the look to match any space. Options include:

- Glossy or matte finishes

- Bold metallics

- Natural earth tones (like a warm, brown epoxy floor)

- Custom multi-color blends

Whether you’re using a metallic epoxy garage floor kit or designing a boutique interior, combining flake sizes and colors gives you full creative control.

With so many options, epoxy flakes allow you to customize everything from epoxy floor texture to overall ambiance—whether you’re going for industrial toughness, subtle elegance, or something in between.

Benefits of Using Epoxy Flakes in Flooring

Incorporating epoxy flakes into your flooring isn’t just about adding some color—multiple practical and aesthetic advantages make them a smart addition to any epoxy cement floor or resin-based surface. Below are some of the key benefits of using flakes in your epoxy floor system:

1. Enhanced Visual Appeal and Surface Camouflage

One of the biggest advantages of epoxy flakes is how they instantly elevate the look of a plain floor. The variety of colors and random patterns breaks up flat surfaces and adds personality to the space. They also do a great job of camouflaging minor imperfections, like small dents, stains, or uneven areas in the concrete or epoxy base layer, giving the floor a smoother and more polished appearance.

2. Added Texture and Visual Depth

Epoxy flakes give your floor a light, decorative texture and a sense of depth, transforming an otherwise basic coating into something far more dynamic. With countless options in terms of flake size, shape, and color, you can create custom designs that match any décor or design vision. Whether you’re going for a bold statement or a more subtle finish, flakes help you get there.

3. Improved Slip Resistance

Adding flakes to the surface introduces a light grit that increases traction underfoot. This makes your epoxy floor safer, especially in areas prone to moisture or heavy foot traffic. Combined with a high solids epoxy base, the flakes also contribute to added strength and durability, helping the floor resist scratches and scuffs from daily use.

4. Easier Floor Maintenance

Epoxy flake floors are also easier to maintain than smooth epoxy coatings. Since flakes help mask dirt, dust, and minor surface grime, your floors stay looking clean longer. When it is time to clean, a simple sweep and mop usually do the trick.

5. Extended Floor Lifespan

Beyond their aesthetic role, flakes serve as a protective layer over the epoxy coating. They absorb some of the wear and tear, helping preserve the underlying epoxy. This can significantly extend the overall lifespan of your epoxy cement floor, making it a cost-effective long-term solution.

Common Applications for Epoxy Flakes

Epoxy flakes are widely used in industrial, commercial, and even residential settings, thanks to their aesthetic appeal and practical performance benefits. These decorative elements can enhance the look and feel of any epoxy floor while also adding texture and durability. Here are some of the most common applications of epoxy flakes:

- Factory and workshop floors

- Warehouse and logistics center flooring

- Flooring in the food and pharmaceutical industries

- Auto repair shops and parking garages

- Retail stores and shopping centers

- Restaurants and cafes

- Hospitals and healthcare facilities

- Schools and universities

- Gyms and sports facilities

- Exhibition halls and galleries

- Garage floors in residential buildings

- Basement and storage room floors

- Patios and balconies

In spaces where hygiene and water-resistance are key—like bathrooms or spa areas—some installers even use clear epoxy for shower floors to achieve a sleek, durable finish. And for those looking to upgrade their surfaces with an easy-to-apply solution, epoxy paint offers a practical alternative for both small DIY projects and larger-scale renovations.

How to Apply Epoxy Flakes?

Applying epoxy flakes is a fairly straightforward process, usually done during the intermediate or final stage of installing an epoxy resin floor. Here’s a step-by-step overview of how it’s typically done:

1. Surface Preparation

Make sure the base layer of epoxy (either the primer or the middle coat) has just been applied and is still wet and tacky. The surface should be even and free of major defects to ensure a smooth application.

2. Broadcasting the Flakes

Grab a handful of epoxy flakes or use a flake broadcast spreader if you’re covering a larger area. Evenly scatter the flakes across the wet epoxy surface. Aim for uniform coverage unless you’re going for a specific pattern or design.

3. Let the Flakes Set

After broadcasting, allow the flakes to sink slightly into the wet epoxy and settle in place. This usually only takes a few minutes. Once the epoxy layer is fully cured (according to the manufacturer’s guidelines), any loose or non-adhered flakes can be removed, typically with a wide scraper or a commercial vacuum.

4. Applying the Topcoat (Optional but Recommended)

To seal and protect the flakes and create a smooth, durable finish, a clear topcoat of epoxy or polyurethane is usually applied. This not only locks in the flakes but also makes the floor easier to clean and maintain.

Ensuring Quality: Choosing Professional Epoxy Flake Installers

In this article, we explored the world of epoxy flakes—what they are, their types, and the many benefits they offer when used in epoxy flooring systems. Hopefully, you now have a clearer understanding of how these decorative elements can enhance both the look and performance of your floor.

If you’re considering applying an epoxy floor in your home, garage, commercial area, or any other space—and you want to include epoxy flakes in the design—our recommendation is to work with trusted and experienced epoxy floor installers to ensure a top-quality result.