The Best Epoxy Commercial Kitchen Floor Paint

Professionals, artists, and do-it-yourselfers are all quickly loving epoxy resin in Brisbane. It’s perfect for obtaining excellent, long-lasting finishes in various uses. Epoxy resin Brisbane is well-known for its visual attractiveness, strength, and flexibility. Epoxy resin offers the ideal fix whether your goals are house repairs, artistic creations, or furniture updates. In this article, we will look deeply into epoxy resin Brisbane in commercial kitchen floor paint and its benefits.

Why Commercial Kitchens Need Epoxy Flooring?

- Commercial kitchen floor paint mostly impacts safety, cleanliness, and efficiency in the hectic environment of a commercial kitchen.

- Thanks in considerable part to its durability and simplicity of use, epoxy resin Brisbane has been the perfect choice for hotels, restaurants, and food manufacturing companies. Epoxy flooring meets the following demands in commercial kitchens.

- Epoxy resin Brisbane flooring is remarkably strong, impact-resistant, and capable of the daily wear and tear of a busy kitchen without cracking or peeling. Commercial kitchens encounter a lot of foot activity and heavy equipment movement, as well as heat and spills.

- Frequent water, oil, and grease spills on the floor increase the slip and accident hazard. Formulated using slip-resistant ingredients, epoxy coatings lower occupational hazards and offer a safer workplace.

- Perfect and non-porous epoxy flooring helps to prevent the accumulation of mold, dirt, and germs in cracks. Moreover, a hygienic food preparation environment is provided by being additionally resistant to chemicals and easily cleaned with usual disinfections.

- Kitchens are always heated and used for many cleaning jobs, requiring a range of materials. Long-term performance free from deterioration and resistant to heat, grease, and strong cleaning agents is guaranteed by epoxy flooring.

- Epoxy flooring is a low-maintenance, quite affordable investment, even with professional installation required. It increases the lifetime of the kitchen floor and reduces repair costs.

- Different colors and treatments of epoxy flooring let companies present a neat and businesslike appearance. You can also customize it to meet a certain brand identity or design aesthetic.

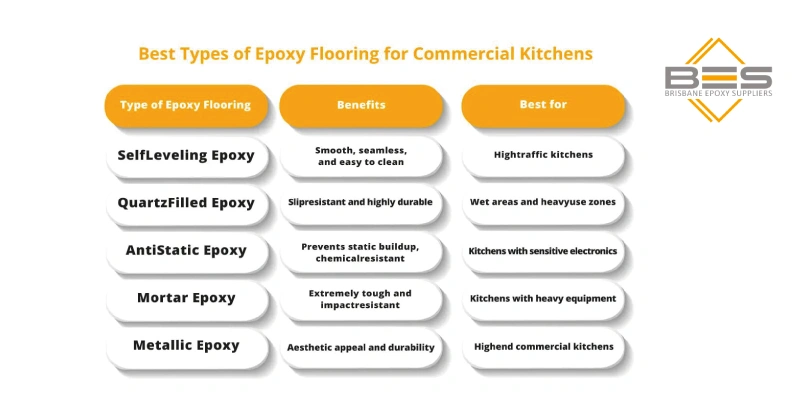

Best Types of Epoxy Flooring for Commercial Kitchens

Commercial kitchen floor paint requires durable, hygienic, and slip-resistant flooring to withstand heavy foot traffic, high temperatures, and exposure to grease, chemicals, and water.

Epoxy flooring is a top choice because it is seamless, easy to clean, and highly resistant to stains and moisture. Below are the best types of epoxy flooring for commercial kitchens.

Commercial Kitchen Floor Paint: The best materials

The quality of the materials in commercial kitchen floor paint determines the installation of epoxy flooring; hence, the perfect tools and instruments are here. Both Alka and Sika epoxy flooring offer easy-to-clean, slip-resistant, and highly durable epoxy paint for your kitchens where there is a lot of foot and machinery traffic.

Alka Epoxy Flooring

Alka coating is specially designed for food-grade places, including commercial kitchens, bakeries, and food processing plants. One of the best products for such places is Alka 112 because it meets the hygienic standards, offering exceptional durability and chemical resistance.

Sika coatings for commercial kitchen floor paint

Sika epoxy flooring is one of the best choices for commercial kitchens, offering durability, safety, and easy maintenance. Designed to withstand the daily challenges of a busy kitchen, it provides exceptional resistance to chemicals, spills, and heavy foot traffic, ensuring a long-lasting and hygienic surface. If you want a Sika product that is aligned with hygienic standards, we recommend the Sika 294, which is suitable for high-traffic areas, and it’s also slip-resistant and will turn your workplace into a safe place.

What Affects the Cost of Commercial Kitchen Floor Paint

Installation cost for commercial kitchen floor paint will depend on the type of epoxy used, the condition of the current floor, the area size, and any specific design or performance demand.

- If the present concrete floor needs significant preparation or has cracks or fissures, more effort and materials will increase the overall cost.

- Bulk material pricing helps larger areas gain from which to maybe reduce the cost per square foot. An overall cost rise will still be driven by the more materials and labor required.

- Including unique designs, colors, or textures will enhance the visual appeal but also raise the cost due to extra materials and work needed.

Flooring in commercial kitchens should be able to resist frequent cleaning, chemical and oil exposure, and heavy foot movement. The total cost will depend on the better-quality epoxy resin Brisbane systems or other protective coatings used to meet these demands.

How to Install Commercial Kitchen Epoxy Flooring

To guarantee a strong, slip-resistant sanitary surface, how to install commercial kitchen epoxy flooring calls for careful preparation and treatment. This is an extensive handbook:

- First: Organize tools and resources. Concrete patching compounds, epoxy resin, Brisbane, and hardener; industrial vacuum; diamond grinder or shot blaster; moisture meter; mixing paddle and drill; roller and squeegee; nonslip additions, if necessary.

- Using a degreaser and pressure washer, clean the floor, removing dirt, grease, and grime.

- Cover holes and cracks with a concrete patching compound; let the compound dry.

- Use a diamond grinder or shot blast to smooth the concrete surface, hence enhancing epoxy adhesiveness.

- Making sure the concrete is dry enough will be made easier with a moisture meter; too much moisture will cause epoxy failure. By removing all waste and dust, one may ensure a clean application surface.

The third stage is the application of epoxy coatings

Epoxy coatings are applied at the third stage of the process. A strong, smooth, long-lasting finish depends on this stage. The main elements of applying epoxy coatings are broken out here:

- An epoxy primer will improve adhesion and allow the concrete to be sealed. Drying it as advised by the manufacturer will enable you to correctly mix the epoxy resin and hardener.

- Fair division of the epoxy on three using a roller or squeezer

- Throw aluminum oxide or silica sand into the wet epoxy for increased slide resistance.

- Applying many coats lets each layer cure before adding the next, depending on the thickness and durability needed.

Fourth: let the Epoxy Cure

Applying the epoxy coating marks only one important step; the next is letting it cure correctly. The chemical process by which epoxy hardens and acquires its full strength, durability, and chemical, moisture, and wear resistance is called curing.

This stage calls for patience since hurrying the process could result in flaws including tacky surfaces, bubbles, or weak areas

- Once the epoxy has been curing for twelve to twenty-24 hours, walk on it. Wait 48 to 72 hours, then run it under food service operations or heavy machinery.

- Maintaining the Epoxy Floor: Every day mop with a non-abrasive cleaner.

- Steer clear of strong, acidic products that could undermine the surface; if the epoxy shows wear, schedule frequent recoatings.

These maintenance techniques will help to extend the lifetime and maintain the excellent quality of your commercial kitchen epoxy flooring.

Daily Hygiene Routine

Maintaining correct hygiene and safety standards is crucial while working with epoxy resin to avoid skin irritation, respiratory problems, and workstation contamination.

Brisbane’s mild and humid temperature might significantly affect the curing process, which emphasizes even more cleanliness. The daily hygiene schedule below safely handles epoxy resin in Brisbane.

- Sweep or dust mop food particles, dirt, and dust to prevent buildup and abrasion.

- To avoid epoxy surface damage, mop with warm water using a pH-neutral, non-abrasive cleaning solution.

- Avoid too much water; although epoxy is water-resistant, stagnant water will eventually break down the sealant, especially near joints.

DIY Against Pro Installation

Different factors influence decisions between professional and do-it-yourself installation for commercial kitchen epoxy flooring.

Benefits of DIY commercial kitchen painting installation:

1. Economically Smart

By handling the project yourself, you save on labor costs, making it a more budget-friendly option.

2. Flexible Schedule

You have the freedom to work at your own pace and choose the best timing for installation.

3. Personal Satisfaction

Completing the project on your own gives a sense of achievement and pride in your work.

4. Ideal for Small Projects

DIY epoxy flooring works best for smaller areas where you have enough time, money, and skill to complete the job properly.

Drawbacks of DIY Epoxy Flooring

1. Time-Consuming Process

Epoxy installation takes time, and without experience, it may take much longer than a professional installation.

2. Risk of Mistakes

Without proper experience, errors like uneven application, air bubbles, or incorrect mixing ratios could reduce the lifespan of your epoxy floor.

3. Equipment Costs

Renting or purchasing essential tools like grinders and shot blasters can be expensive, adding to the overall cost.

4. Limited Expertise

Professionals have years of experience handling complex areas like corners, cracks, and seams, ensuring a seamless and durable finish.

5. Faster Installation by Professionals

A professional team can complete the job much quicker and ensure a smooth, long-lasting surface using the right techniques.

Long-Term Durability

- A professional project is more likely to endure wear and tear and last; piece of mind benefits from that.

- Negatives: Higher Cost: Labor expenses could increase the total cost, especially for bigger regions.

- Scheduling: The professional’s calendar can request adjustments meant to delay the hiring. Less Control: The speed and minute intricacies of do-it-yourself projects will elude you more easily.

- Larger, high-traffic commercial kitchens, or if you want a perfect finish and lifetime with limited possibility for error, here are the best for.

Final thoughts

In commercial kitchen floor paint, from artistic expressions to practical uses, epoxy resin Brisbane provides a flexible and strong answer for a wide spectrum of undertakings.

Whether you prefer professionally or do-it-yourself projects, epoxy resin is a must-have material since it can provide beautiful finishes, durable surfaces, and bespoke designs.

Epoxy resin is a game-changer for building, home remodeling, and even industrial purposes in Brisbane because of its long-lasting resilience, simplicity of use, and pleasing appeal. Don’t ignore the several opportunities; next job, utilize epoxy resin, and see the workmanship and quality it produces!