Is Self-Leveling Epoxy Resin the Right Choice for Your Floors?

Did you know that with self-leveling epoxy resin, you don’t have to worry about cracked and damaged concrete floors anymore? This kind of epoxy floor can create a smooth and seamless floor, even on cracked concrete floors! Amazing, isn’t it? Also, this kind of epoxy is much better for DIY projects compared to other kinds of epoxy floor coatings.

You can also use it in different buildings with versatile uses. If you’re not familiar with self-leveling epoxy floor coating and its benefits, stay tuned to find out everything about it.

What Is Self-Leveling Epoxy Resin?

What is self-leveling epoxy resin? The components of self-leveling epoxy floors are no different from other kinds of epoxy resins. It consists of epoxy resin and hardener. The only difference between usual epoxy resin and self-leveling epoxy resin is that self-leveling epoxy resin can spread out and fill cracks or imperfections on the floor.

It doesn’t matter if it’s a commercial or residential building; if you want to achieve a high-gloss, seamless, and modern floor, self-leveling epoxy floor coating is your best choice ever.

Best Places to Use Self-Leveling Epoxy Floor

Self-leveling epoxy resin has an adaptable nature. Therefore, we can use it in different places. Some of the best places to benefit from this smooth, easy-to-clean, and durable surface are as follows:

1- Residential Buildings

Most people choose self-leveling epoxy floor coating for their DIY projects in homes and residential buildings. Its combination of style, ease of maintenance, and longevity makes it a perfect choice for residential buildings. Where can you use it in your home?

- Garages

- Basements

- Kitchen and living rooms

- Bathrooms

2- Commercial Settings

If you are searching for a flooring for offices and retail stores that is both practical and beautiful, then epoxy resin flooring is your best choice. In addition, epoxy flooring offers a durable and unique surface that leaves a lasting impression on customers and clients. These are the best places where you can use epoxy floor coating:

- Retail Stores

- Showrooms

- Office Spaces

3- Industrial and Manufacturing Buildings

When it comes to choosing the best flooring option for industrial settings, you need to consider many different factors. The most suitable type of flooring for these places is the one that can withstand heavy machinery, chemical spills, and constant movement of materials. In addition, epoxy resin floors can easily be cleaned and maintained, and you don’t need to use harsh chemicals on them. These are the best places you can use self-leveling epoxy resin floor coating.

- Warehouses

- Factories

- Laboratories

- Chemical Plants

Advantages of Using Self-Leveling Epoxy Floor Coating

Self-leveling epoxy floor coating offers numerous benefits that make it a popular choice among people. Due to its high-performance characteristics, we can use it in many different buildings with versatile uses. Here’s a list of the most important benefits of self-leveling epoxy coating:

- Self-Leveling Nature: With self-leveling epoxy, you don’t have to worry about small holes and cracks anymore. It automatically spreads over the floor and fills low spots and cracks.

- High Gloss and Aesthetic Appeal: This kind of epoxy always produces a shiny, reflective finish that attracts everyone’s attention. It’s amazing, isn’t it? You can easily use it in warehouses and residential buildings as well.

- Durability and Strength: Epoxy resin flooring is resistant and can withstand heavy traffic, chemicals, and mechanical wear. You don’t have to change the floor coating after 2 or 3 years, as epoxy floor coating lasts for years to come.

- Waterproof: If you are worried about moisture in your place, epoxy resin flooring is your best choice. Self-leveling epoxy resin is resistant to moisture. That’s why it’s a suitable choice for damp places.

Best Self-Leveling Epoxy Resin Brands

If you want something that can last for a long time, we strongly recommend choosing one of the best and most durable epoxy resin brands. Here are some of the most reliable brands.

1- ALKA 110 Kit: It’s one of the high-performance, self-smoothening epoxy resin coatings that creates a long-lasting finish. ALKA 110 epoxy resin is suitable for heavy-duty applications.

2- Rust-Oleum Epoxy Shield: It’s one of the best epoxy resin coatings that is suitable for DIY projects and professionals’ use alike.

3- ALKA 110S Kit: ALKA 110S is one of the strongest, resistant, and durable epoxy floor coatings that is suitable for industrial, commercial, and DIY projects.

4- Ultra Clear Epoxy: This product creates a crystal-clear finish and offers a highly durable surface. It’s the best possible choice in places where aesthetics is a priority.

5- Sikafloor 264 Kit: It is 100% solid, and you can use it in various buildings with versatile uses. Sikafloor 264 consists of two components, and it is extremely easy to spread.

6- Sikafloor 94 Filler: With its easy mixing and anti-slip characteristics, it is considered one of the best choices for commercial, industrial, and even residential buildings. Sikafloor 94 Filler is durable and creates a safe environment for users.

Factors to Consider Before Applying Self-leveling Epoxy Resin

If you’re going to apply the epoxy yourself, you need to pay careful attention to some specific factors. These factors affect the result directly.

Environment’s Moisture

The floor must be completely dry before epoxy application. Therefore, it’s necessary to perform a moisture test to make sure that the floor is dry enough for epoxy application. If the floor is wet and you still apply the epoxy, it can lead to peeling or bubbling over time.

Temperature and Humidity of the Place

Very high or low temperature and humidity level have negative effect on epoxy application and curing process. For achieving the best possible result, it’s necessary to apply the epoxy in controlled conditions. If you want the epoxy resin to create a strong bond to the floor and even finish, it’s better to control the temperature and humidity level during applying and curing time.

Condition of Substrate

It’s one of the most important factors for achieving the best possible result. Large and unusual cracks, holes, or uneven surfaces can impact the quality of the epoxy finish. Inspect and fix these problems beforehand to make sure that the epoxy floor coating adheres well to the substrate.

Adequate Ventilation

If applying epoxy floor is a DIY project for you, then you need to use protective gear during epoxy application. Epoxy resin releases poisonous fumes during mixing, application, and curing. Make sure that the ventilation is adequate and use protective gear (mask, gloves, and goggles) during application.

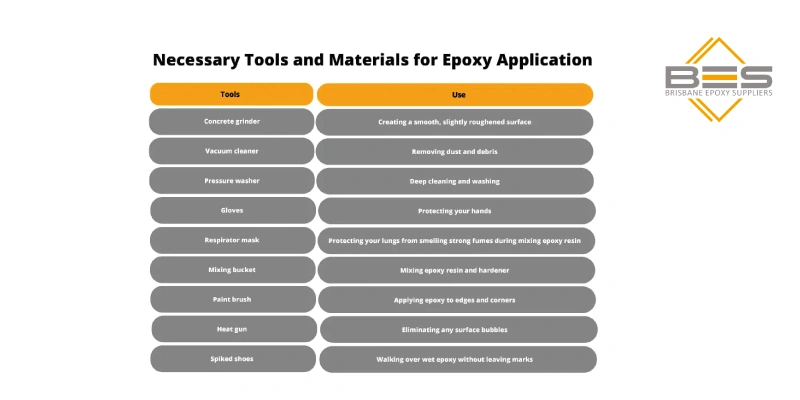

Necessary Tools and Materials for Epoxy Application

You need to prepare the floor before epoxy application. For better results, it’s essential to prepare the necessary tools and materials. Here’s a complete list of all the tools that you’re going to use during the process.

How to Prepare the Floor before Self-Leveling Epoxy Resin Application

Preparing the substrate is the first and most important step in the process of epoxy application. Here’s a complete guide about how to properly prepare the floor before self leveling epoxy resin application.

1- Clean the Floor Thoroughly!

Use a vacuum cleaner and a brush to remove any dust, grease, and debris from the floor. If there’s a stubborn stain on the floor, use a degreasing cleaner and a pressure washer to remove the stain. These stains could interfere with the epoxy’s adhesion.

2- Repair and Fix Cracks

If you see any cracks or holes in the floor, you must fill them with a concrete patching compound or epoxy filler. It’s essential to smooth out the surface before epoxy application. Remember to let the floor dry completely before proceeding.

3- Etch the Surface

Here’s a tricky step! Etching the floor before epoxy application will help the epoxy bond better with the substrate. Etching creates a slightly rough surface that improves adhesion. You can either use a commercial etching product or sand the surface lightly.

4- Apply the Primer

Do you want epoxy resin to adhere better to the substrate? Then, apply a layer of primer before epoxy application. In addition, applying a layer of primer will prevent air bubbles from forming during epoxy application. You can just enjoy a smooth and consistent final coat.

5- Apply the Self-Leveling Epoxy Resin

Read the manufacturer’s instructions on the bucket carefully, and mix epoxy resin and hardener according to those. Be careful with that! Because an inadequate mixing ratio can result in improper curing or a weak finish. Then pour the epoxy in small sections and use a roller to spread it evenly on the floor.

6- Let it Dry

Finally, just let the surface dry for about 48 hours. Then you can walk on the surface easily and enjoy your epoxy floor coating.

Self-leveling epoxy flooring is a key to achieving a long-lasting and flawless finish that can last for years to come. If you are still unsure about choosing the best brand of epoxy, we are here to help.

Conclusion

Ultimately, self-leveling epoxy resin is an excellent choice for those seeking a smooth and even coating for their floors. This epoxy can easily fill cracks and damage in the surface, creating a clear and durable finish that is suitable for various spaces, including residential, commercial, and industrial environments. With features such as high durability, a glossy appearance, and moisture resistance, this epoxy coating not only meets your practical needs but also enhances the aesthetic of your space. So, if you’re looking for a reliable and cost-effective flooring solution, self-leveling epoxy resin is a smart choice.