Polyaspartic vs Epoxy Garage Floor: Which One Should You Choose?

When it comes to upgrading your garage floor, the choice often comes down to polyaspartic vs epoxy garage floor coatings. Both offer durable, attractive finishes that protect your concrete and enhance its appearance. But which one is right for your space, budget, and long-term goals? In this guide, we’ll break down the pros and cons of each option to help you make the best decision for your garage.

What is Polyaspartic?

Polyaspartic is one of the latest generation floor coating systems, which has gained a lot of market attention in the past few years because of the short drying time that it offers. A polyaspartic coating normally takes only one day to apply and is usually ready for use, especially for foot traffic in a few hours. It also gives considerable hardness and chemical immunity that may make it ideal for using in garage flooring.

Polyaspartic Flooring Pros and Cons

When trying to figure out all aspects of epoxy vs. polyaspartic garage floor coating, we recommend knowing the pros and cons of each option. Here we have given the information you need for each one:

Pros:

- Fast drying and curing time: In the worst-case scenario, you can have a brand new garage floor finished and ready for use in the next twenty-four hours.

- UV resistant: Polyaspartic coatings do not tend to turn yellow or fade even under the effects of direct sunlight, thus preserving the glossy appearance of the coating.

- High gloss finish: In terms of sheen, polyaspartic will give you an as good as new appearance with a high gloss polish.

Cons:

- Significantly more expensive than epoxy: It is advisable to know that it would cost about 4-5 times more expensive per square meter than epoxy to use polyaspartic coating.

- Requires professional installation: Polyaspartic is a difficult material to apply and should not be used when undertaking a Do-It-Yourself exercise. This means that you will have to get the services of a contractor.

- Strong odor during application: The smell of chemicals during the coating is rather intense; therefore, it is critical to ensure proper ventilation.

- Not a DIY-friendly option: As compared to epoxy, polyaspartic is not a coating that you can easily apply by a DIY method.

What is Epoxy Coating?

Epoxy is a tested and trusted garage flooring solution that has remained a popular favorite among homeowners and professionals alike for years. It is an extremely hard-wearing and long-lasting coating comprising of liquid resins and hardeners. When combined, these several parts combine to make a rigid plastic material that covalently adheres to concrete and offers more protection. When installed and maintained correctly, an epoxy floor coating is likely to last over a decade, thus making it a worthy investment in the longer run regarding polyaspartic vs. epoxy garage floor coating.

Pros and Cons of Epoxy Garage Flooring

Pros:

- Highly durable: Epoxy produces a hard-wearing, non-crevice surface that lacks the tendency to crack, chip, stain, buckle to chemical attack, and abrasion.

- Customizable appearance: Epoxy can be as plain as you want with various color pigments and it can also have decorative color chips or even metallic powders.

- Affordable: Epoxy is considerably cheaper compared to polyaspartic, particularly if you choose to purchase a DIY kit.

- DIY-friendly: By learning how to apply an epoxy coating properly, you might be able to complete the job yourself as well as save money on the workforce.

Cons:

- Longer drying and curing time: It will probably take you 24-72 hours not to use the garage floor to give room for the epoxy to dry and harden.

- Can yellow with UV exposure: Some epoxy that costs less and do not contain UV inhibitors may get a yellow hue after some time if they are exposed to direct sunlight. This problem will, however, be greatly reduced when one chooses a high-grade product.

Polyaspartic vs. Epoxy: Which One is More Suitable?

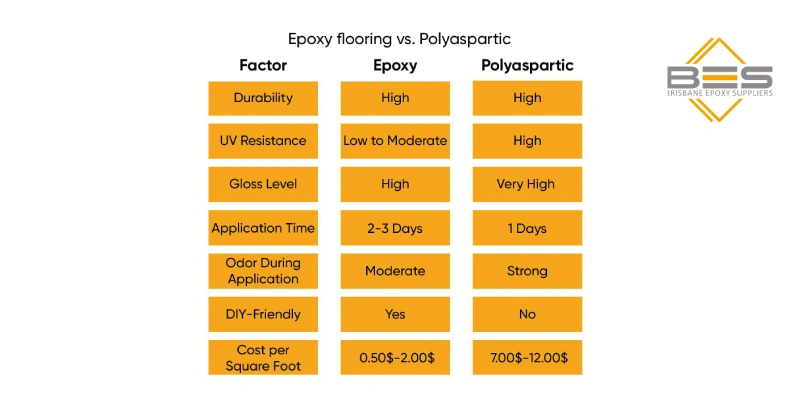

In terms of polyaspartic vs. epoxy garage floor coating, when the differences between the two types of garage floor coatings are compared directly based on factors such as durability, appearance, ease of application, and cost, then it can be seen that epoxy has certain advantages over the other types.

Why Epoxy is the Better Investment

Garage floor epoxy coating delivers practically the same protective, compelling features that polyaspartic does, but at a far lower cost. In many household garage environments, epoxy suffices well enough to deliver the optimum of protection and performance. One thing you must understand about epoxy is that it is more affordable compared to polyaspartic for a more beautiful and lasting garage floor. Epoxy is also appropriate for the homeowner with a desire to DIY since it is relatively easier to apply, and it has a longer working time during the application of the coating.

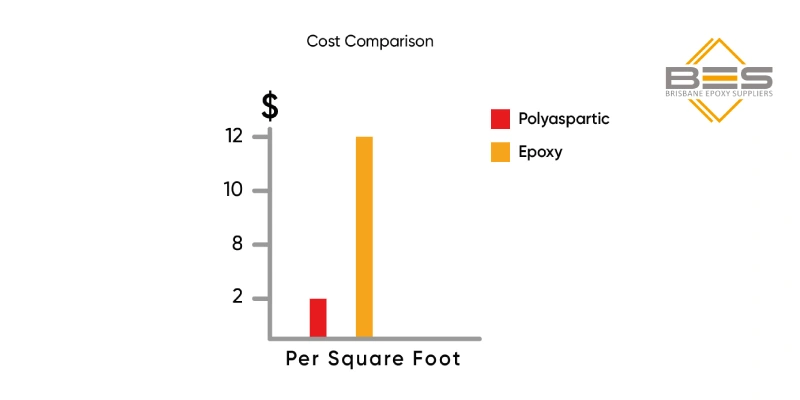

Cost Comparison: Epoxy Wins in Affordability

Regarding polyaspartic vs epoxy garage floor coating, the cost of a polyaspartic floor coating for an average-sized garage, when done by experienced professionals, costs between $7 and $12 per square foot. DIY epoxy kits, on the other hand, can be bought at a relatively low cost of roughly $0.50-2.00 per square foot. In fact, for a typical two-car garage that ranges from about 400 to 500 sq ft, going for epoxy will be cheaper by $1500 or more than polyaspartic. Notice that polyaspartic is costlier than epoxy, and even if you hire professionals to install the epoxy floor, you are likely to benefit.

Materials and Tools Required

For anyone thinking about doing the epoxy floor coating on their own, you will be glad to know that this is a project that most homeowners can easily handle. For the application to be successful, you should acquire an epoxy kit with the right proportion of resin and hardener and colorful chips if you wish to create an aesthetic appeal. Other must-have supplies include:

- A floor grinder or a heavy-duty sander for proper surface preparation

- Squeegee and nap roller for spreading and back-rolling the epoxy

- Spiked shoes for walking across the wet epoxy during application

- Several mixing buckets and stir sticks

- Rubber gloves, safety glasses, and a respirator mask for protection

If you take your time and prepare your concrete surface correctly and pay close attention to the mixing and application instructions, you too can go from a boring old stained garage floor to a beautiful high-gloss epoxy coating in less than a weekend of work. Create an icon-based infographic highlighting the tools and materials needed for a successful DIY epoxy floor coating project.

Final thoughts

When comparing polyaspartic vs epoxy garage floor coating, epoxy remains the smarter and more cost-effective option for most homeowners. Its balance of affordability, durability, and ease of application makes it ideal—especially for DIY enthusiasts. While polyaspartic coatings cure faster and resist UV light better, they come with a much higher price tag and require professional installation. Unless you specifically need the fast turnaround and UV protection polyaspartic offers, epoxy is a reliable, proven solution that delivers excellent performance without breaking the bank.